Objective

To heat aluminum molding to activate an adhesive coating prior to applying the vinyl.

End Product

Automotive Trim

Equipment

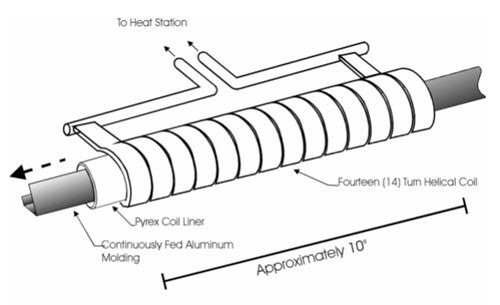

Ambrell EKOHEAT® 20 kW power supply including a remote work head holding three capacitors totaling 0.83 µF. A specially designed 14-turn helical coil made from 1/2" (12.7 mm) flattened copper tube.

Materials

Aluminum molding folded from a flat sheet measuring 2" (51 mm) wide and 0.03" (0.8 mm) thick. The final form measures 5/8" (16 mm) by 1" (25 mm).

Temperature

500 ºF (260 ºC)

Frequency

118 kHz

Testing

Processing was continuous at a rate over 20 feet (6.1 m) per minute with the temperature reaching 500 °F (260 ºC). The aluminum was formed from a roll of flat sheet, after which the molding was coated with adhesive and was sent through the induction coil. It was critical that warping of the molding be kept to an absolute minimum.

Heating to the target temperature was accomplished through the se of the unique helical induction coil; molding was continuously processed at a rate over 20 feet per minute. Due to the even heating produced through induction, warping of the aluminum molding was kept to a minimum.

Benefits

-

Precision and efficiency: This was critical, as precision heating prevented warping of the aluminum molding.

-

Higher production rate: Along with meeting quality objectives, induction met the targeted production rate.

-

Minimal Warping: Thanks to induction’s even heating.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000