Objective

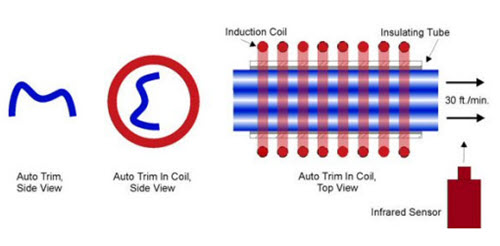

To heat various sizes of aluminum auto trim to 500°F (260°C) at a rate of 30 ft. (9.1m) per minute for curing an adhesive.

End Product

Auto trim

Equipment

Ambrell 20 kW induction heating system equipped with a remote workhead with six 0.75µF capacitors for a total capacitance of 0.5 µF

An induction heating coil designed and developed specifically for this application.

Materials

Magnetic steel and aluminum auto trim parts, coated with adhesive; 1.85” (47mm) ID ceramic tube

Temperature

500 °F (260°C)

Frequency

157 kHz

Testing

To simulate continuous production, a slide table/stepping motor arrangement and ceramic tube are used to move the parts through the eight turn helical coil at 30 ft. (9.1m) per minute. In continuous production, an infrared sensor can be used to measure the temperature of the aluminum after exiting the coil and adjust output of the power supply to maintain the required 500 °F (260°C).

Benefits

-

Consistent, controllable heat

-

Hands free operation

-

Reliable, repeatable results

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000