Objective

To heat three steel parts for a bending application; the end products are cutting tools and they’re looking to upgrade their torch brazing process.

End Product

Steel parts

Equipment

Ambrell EKOHEAT® 10 kW, 50-150 kHz induction heating power supply with a workhead and coil specifically designed for this bending application.

Materials

Magnetic steel

Temperature

1400 ºF (760 ºC)

Frequency

100 kHz

Testing

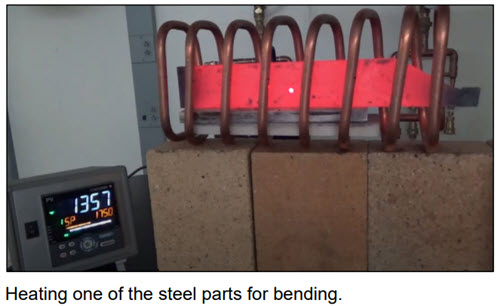

A custom-designed single position multiple-turn helical coil was built to generate the required heating for this bending application. Initial tests were conducted to optimize the power delivered to the part. Temperature indicating paint was then applied, which dissolves when the part reaches target temperature. All three parts achieved the target temperature within two minutes. They reached as high as 1,800°F (982 ºC) within four minutes.

Benefits

-

High efficiency, low energy consumption heating method

-

Fast, controllable and repeatable process, a key benefit when compared to torch heating

-

Hands-free heating that involves no operator skill for manufacturing

-

Even distribution of heating

-

Safety benefits when compared to the open flame and heat introduced into the work environment with torch heating

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000