Objective

To heat a weld seam

End Product

Galvanized steel tubes

Equipment

Ambrell EASYHEATTM 4.2 kW, 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials

Stainless steel and galvanized steel

Temperature

1300 ºF (704 ºC)

Frequency

N/A

Testing

A piece of ceramic was secured to the bottom of the coil to serve as a stop-block for consistent positioning of the coil with respect to the parts. Temperature indicating paint was then applied to the part, which dissolves when the part reaches target temperature.

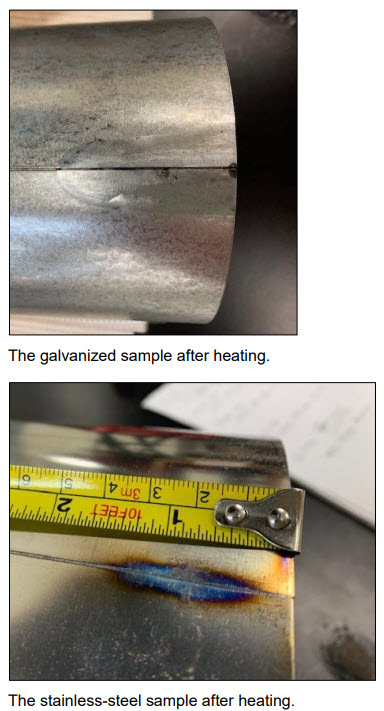

Heating the galvanized steel tubes to temperature took 6 seconds. There was very little discoloration to the sample. The stainless-steel tubes were tested at those settings but took longer to reach the target temperature and had more discoloration to the heated area. However, it was found that the annealing temperature for the stainless-steel sample was 1000 oF (538 oC), and it only took 6 seconds to heat the stainless-steel sample to that temperature.

Benefits

-

Speed: Induction achieved the client’s speed requirements.

-

Footprint: The client is building a system with induction, and induction’s modest footprint works well within the system.

-

Repeatability: With induction you can expect the same result every time.

-

Expertise: The client took advantage of THE LAB’s expertise to prove out their process.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000