Objective

To heat a variety of copper tubes for annealing applications; the end products are formed tubes and pipes for various industrial uses

End Product

Copper tubes

Equipment

Ambrell EKOHEAT 100 kW, 15-40 kHz induction heating system equipped with a remote workhead containing eight 10 μF capacitors for a total capacitance of 20 μF

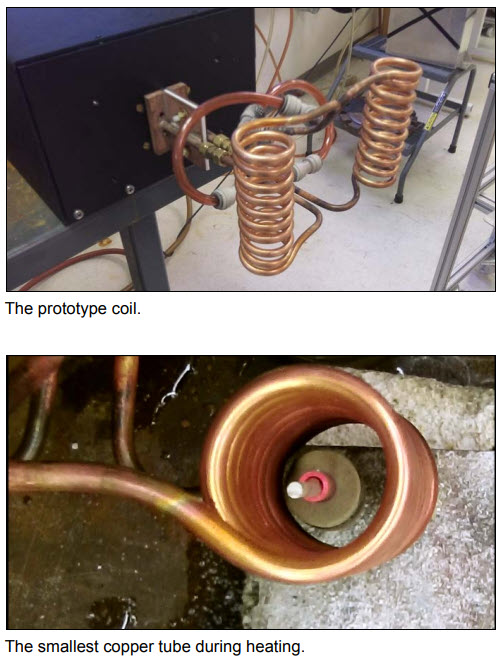

A multiple position ten-turn helical induction heating coil

A multiple position ten-turn helical induction heating coil

Materials

Customer supplied copper tubes (height up to 5.5”/ 140 mm and a diameter up to 0.7”/ 17.8 mm)

Temperature

1200 ºF (649 ºC)

Frequency

24 kHz

Testing

Initial testing was conducted to optimize the power delivered to the tubes. An EKOHEAT 35 kW/30 kHz induction power supply was used and the power requirements for actual production were calculated based on testing. With a 100 kW power supply, copper tubes – up to the largest diameter required – can be heated to temperature within five seconds. A prototype coil was used during testing,

Benefits

Speed: Copper tubes of various geometries heated to temperature in a matter of seconds

Repeatability: Induction offers the same result every time, which makes it ideal for a potentially high volume process such as this one

Footprint: Induction requires a minimal footprint so it’s easy to integrate into production environments

Ambrell Lab Expertise: The client leveraged the lab to come up with the right induction solution based on their production requirements

Repeatability: Induction offers the same result every time, which makes it ideal for a potentially high volume process such as this one

Footprint: Induction requires a minimal footprint so it’s easy to integrate into production environments

Ambrell Lab Expertise: The client leveraged the lab to come up with the right induction solution based on their production requirements

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000