Objective

To heat a stainless steel tube while avoiding oxidation for an annealing application; the end product is a handle for a dental tool

End Product

Dental tools

Equipment

-

Ambrell EASYHEAT LI 4 kW, 150-400 kHz induction heating system equipped with a remote workhead containing two 1.5 μF capacitors for a total capacitance of 0.75 μF

-

A single position three-turn helical induction heating coil

Materials

-

Steel tube

-

Hydrogen gas

-

Bell jar and fixture

Temperature

1900 ºF (1038 ºC)

Frequency

270 kHz

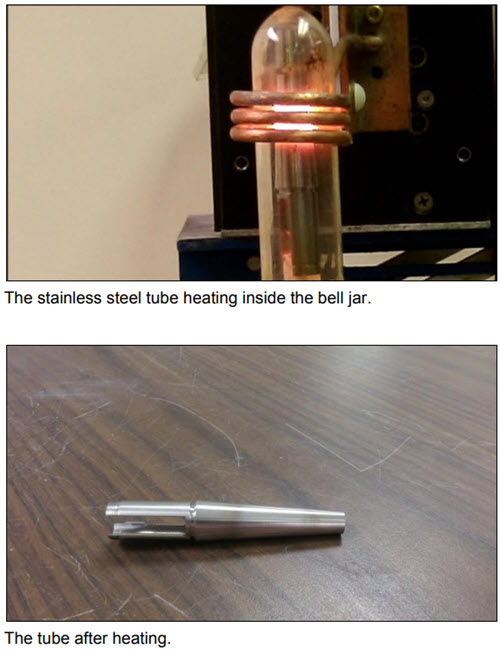

Testing

The tube was placed in a tube and connected to hydrogen. A bell jar was placed over the tube to trap the hydrogen gas. Hydrogen was allowed to flow into the bell jar for one minute. Power was then turned on and the part began to heat. The part achieved annealing temperature within five seconds. Power was turned off and the part was allowed to cool for one minute.

Benefits

-

Speed: The part heated to required temperature in a matter of seconds

-

Repeatability: Induction offers the same result every time, which makes it ideal for a high volume process such as this one

-

Ambrell Lab Expertise: The client leveraged the lab to come up with the right induction solution based on their specifications; the client was outsourcing the process but

-

thanks to a better solution that mitigates the oxidation issue they are willing to bring it in house

-

Increased Production Efficiency: The previous oxidation issue forced them to polish the handles which added a step in their manufacturing process

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000