Objective

To heat ammunition casings for shell annealing

End Product

Shell casings

Equipment

-

Ambrell EKOHEAT 30 kW, 50-150 kHz induction heating system equipped with a remote workhead containing eight 1.0 μF capacitors for a total capacitance of 2.0 μF

-

A single position two-turn helical induction heating coil

Materials

Ammunition casings (7.62 mm/0.3”)

Temperature

1250 ºF (677 ºC)

Frequency

113 kHz

Testing

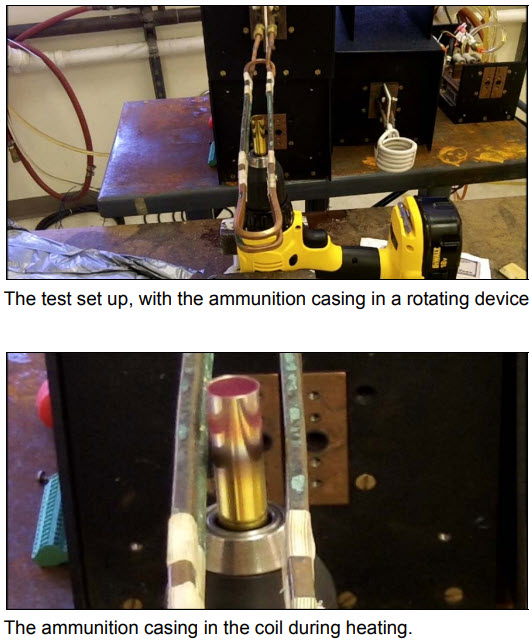

The coil, which is approximately 305 mm (12”) long to enable several casings to be heated concurrently, is set up to simulate a production situation. A rotating device is used, which simulates the conveyor set up that will be present in production. With a three second heating time, 240 parts per minute can be annealed.

Benefits

-

Speed: The client will be able to increase throughput when compared to their current torch heating process

-

Repeatability: Induction offers the same result every time, while a torch often delivers variation

-

Safety: There is no open flame with induction

-

Ambrell Lab Expertise: The client leveraged the lab to come up with the right induction solution based on their specifications

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000