Objective

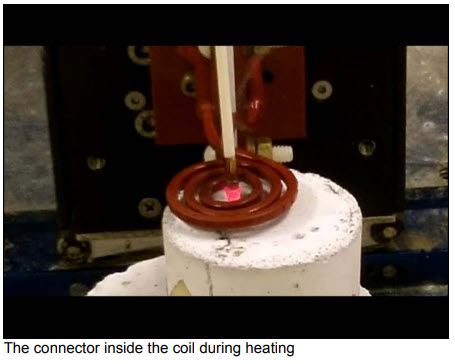

Heating a copper wire connector to 1400 ºF (760 ºC)

End Product

Copper connector

Equipment

-

Ambrell EASYHEAT 8310 LI, 10kW 150-400 kHz induction heating system equipped with a remote heat station containing two 1.0 μF capacitors

-

A single position three-turn pancake induction heating coil designed and developed specifically for this application

Materials

Various copper wire crimps (connectors)

Temperature

1400 ºF (760 ºC)

Frequency

390 kHz

Testing

It was determined that the three-turn pancake coil was best for providing the right amount of heat to anneal the connector effectively. The wire connectors heated in 1.7 seconds or less.

Benefits

-

Speed: The proposed process met the client’s time objectives

-

Versatility: The client wanted to be able to heat parts of various sizes, which was achieved with a concentrator coil

-

Lab expertise: Given that this is a new process for the client, Ambrell’s lab expertise proved very valuable when creating the process

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000