Objective

To heat steel wire that is 0.04” (1 mm) in diameter to 2012 °F (1100 °C) within three seconds

End Product

medical wire

Equipment

-

Ambrell EASYHEAT 8310 LI 10kW/150-400 kHz induction heating system equipped with a remote heat station containing two 1.5 μF capacitors

-

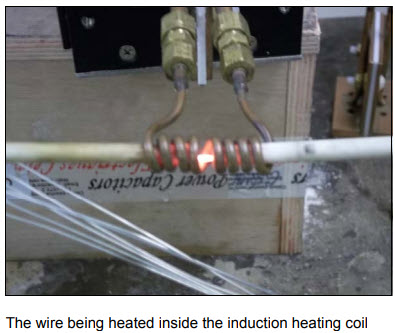

A single position eight-turn helical coil designed and developed for this application

Materials

Steel wire (0.04”/1 mm)

Temperature

2012 ºF (1100 ºC)

Frequency

350 kHz

Testing

The wire was placed into the coil, and an optical pyrometer was focused onto the part. The power was turned on to the induction power supply, and the part began to heat. Within three seconds, the target temperature of 2012 ºF (1100 ºC) was achieved. The client would like to heat both ends of the wire at the same time, which is achievable with two systems and two coils.

Benefits

-

Speed: The wire achieved the targeted temperature within three seconds

-

Quality control: Due to bringing the process in house, the client will have better control over the end product

-

Responsiveness: Ambrell was able to perform a free laboratory test and design a process that could enable the client to bring the process in-house in a cost efficient manner, and even connect them with an automation partner to maximize productivity

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000