Objective

To anneal a variety of part sizes of a common shape in-line (continuously) from a high speed punch press.

End Product

stainless steel dental crowns

Equipment

-

Ambrell 3542LI 3.5kW induction heating system, equipped with a remote workhead containing two 1.5μF capacitors

-

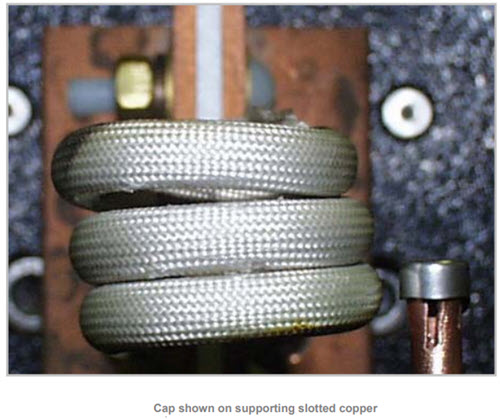

An induction heating coil designed and developed specifically for this application.

Materials

304L stainless steel caps

Temperature

1600-1800°F (870-980°C)

Frequency

308 kHz

Testing

A 3-turn coil is used for the heating pattern. Sample cap is placed on a copper tube (slotted to reduce heat-loss) and inserted into a quartz tube which is filled with nitrogen. RF

energy is applied for a cycle time of 500 milliseconds. Three S.S. cap sizes (0.295" to 0.397” OD) Each one of the three cap sizes were heated at two different settings.

Requirement to anneal large quantities of work-hardened crowns suggests induction for precise, controllable heating. Since oxidation is unacceptable in the finished product,

Induction is the appropriate choice for heating in an inert atmosphere.

Benefits

Induction heating provides:

-

Rapid, repeatable results

-

Integration-friendly equipment for high-speed automation

-

Operability in an inert atmosphere

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000