Objective

Annealing the end of a steel hydraulic motor shaft prior to machining

End Product

motor shaft

Equipment

-

Ambrell 4.2 kW induction heating system, equipped with a remote workhead containing one 1.0 µF capacitor

-

An induction heating coil designed and developed specifically for this application.

Materials

0.75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end

Temperature

1350 ºF (732 ºC)

Frequency

259 kHz

Testing

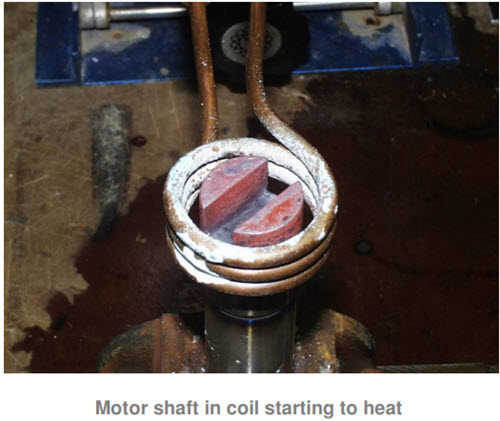

A three-turn helical coil is used for annealing the motor shaft. The end of the motor shaft is placed in the coil and power is applied for 20 seconds to reach 1350 ºF (732 ºC) and turns the steel red hot

Benefits

Induction heating provides:

-

High efficiency, low energy cost

-

Precise and controllable placement of heat to anneal only the required area

-

Faster production process

-

Consistent results

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000