Objective

To anneal aluminum fuel tank fill necks to 650 ºF (343 ºC) for bending.

End Product

fuel tank fill necks

Equipment

Ambrell EKOHEAT® 30 kW, 50-150 kHz solid state induction heating power supply with a workhead and coil specifically designed for this application.

Materials

Aluminum fill neck 2.5” (63.5 mm) diameter, 14” (35.5 cm) long

Temperature

650 ºF (343 ºC)

Frequency

75 kHz

Testing

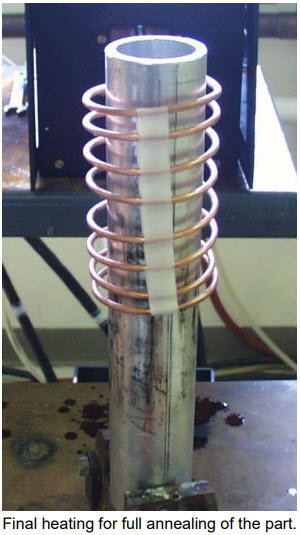

An eight-turn helical coil was used to heat the tube for annealing. To anneal the full length of the tube, the tube was placed in the coil and heated for 30 seconds, then rotated, and the bottom half was heated for an additional 30 seconds. The tube was then bent while hot to prevent cracking.

Benefits

-

High efficiency, low energy consumption

-

Fast, controllable and repeatable process

-

Prevention of cracks Hands-free heating that involves no operator skill for manufacturing

-

Even distribution of heating

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000