Objective

Annealing of the affected zone of a saw blade after the stellite tips have been welded in place

End Product

Saw blades

Equipment

-

Ambrell 2.4 kW induction heating system, equipped with a remote workhead containing two 0.33µF capacitors for a total of 0.66µF

-

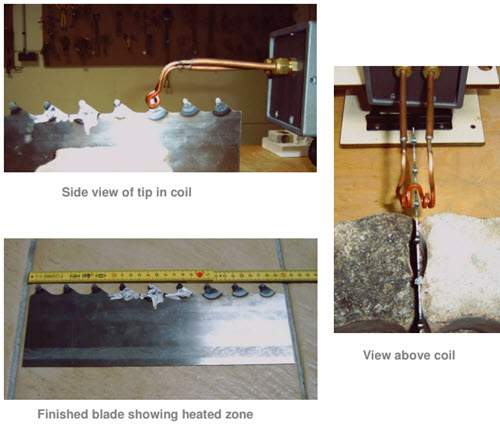

An induction heating coil designed and developed specifically for this application.

Materials

C75 carbon steel saw blade with stellite tip 0.06” (1.5mm) thick with a blade height of 0.55” (14mm)

Temperature

1292 ºF (700 ºC)

Frequency

390 kHz

Testing

A split four-turn helical coil is used so the blade can move evenly though the coil. Each tip of the blade is heated for 5 seconds as it passes through the coil to anneal the affected

area.

Benefits

Induction heating provides:

-

Repeatable, rapid and accurate heating cycles which are ideal for in-line production processes because induction can produce

-

Hands-free heating that involves no operator skill for manufacturing

-

Non contact and energy-efficient heat

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000