Objective

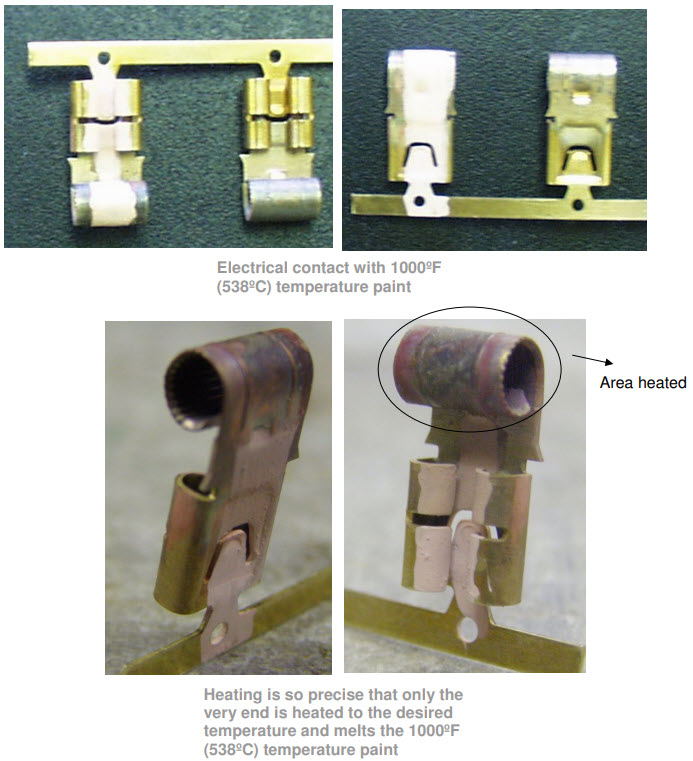

To anneal a small area of an electrical contact for crimping

End Product

Female spade contact

Equipment

-

Ambrell 10 kW induction heating system, equipped with a remote workhead containing two 1.0µF capacitors for a total of 0.5 µF

-

An induction heating coil designed and developed specifically for this application.

Materials

Brass female spade electrical contact with single transverse loop at end 0.5”(12.7mm) long, 0.25” (6.3mm) wide and 0.03” (0.8mm) thick, 1000ºF (538ºC)heat paint

Temperature

1000ºF (538ºC)

Frequency

310 kHz

Testing

A one turn hairpin coil is used to heat the electrical contact to 1000ºF (538ºC) in 1.5 seconds. The contacts are in strips at 0.75” (19mm) centers and will run continuously at a rate of 50’ (15.24m) per minute.

Benefits

Induction heating provides:

-

Hands-free heating that involves no operator skill for manufacturing

-

Pinpoint accuracy

-

Consistent results

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000