Objective

Heating a titanium fastener to 1100-1450ºF (593-788ºC) for an annealing process.

End Product

Titanium fasteners

Equipment

-

Ambrell 10.0 kW induction heating system, equipped with a remote workhead containing one 0.66µF capacitor.

-

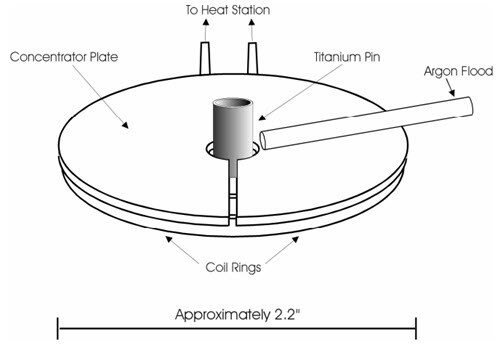

An induction heating coil designed and developed specifically for this application.

Materials

0.06” (1.5mm) high zone on a titanium fastener measuring 0.163-0.375” (4.14-9.52mm) in diameter and 0.5-3.0” (12.7- 76.2mm) in length

Temperature

1100-1450ºF (593-788ºC)

Frequency

145 kHz

Testing

A three turn concentrator plate coil is used to heat the fastener for 0.2 seconds. This is an automated process that includes robotic placement of parts in the coil from a bowl fed track while Argon gas is flooded across the part to prevent oxidation. The parts are processed at a rate of 1000 parts per minute.

- 1800 ºF was reached in 10 seconds. • The production rate of 1 part every 5-10 seconds was met.

The above results were achieved through the use of a 39 turn helical style work coil measuring 1 1/2" ID and 11 1/2" OAL.

Benefits

Induction heating provides:

-

Can be incorporated easily with pick and place robotics.

-

Flameless process.

-

Heating is limited to the specific area.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000